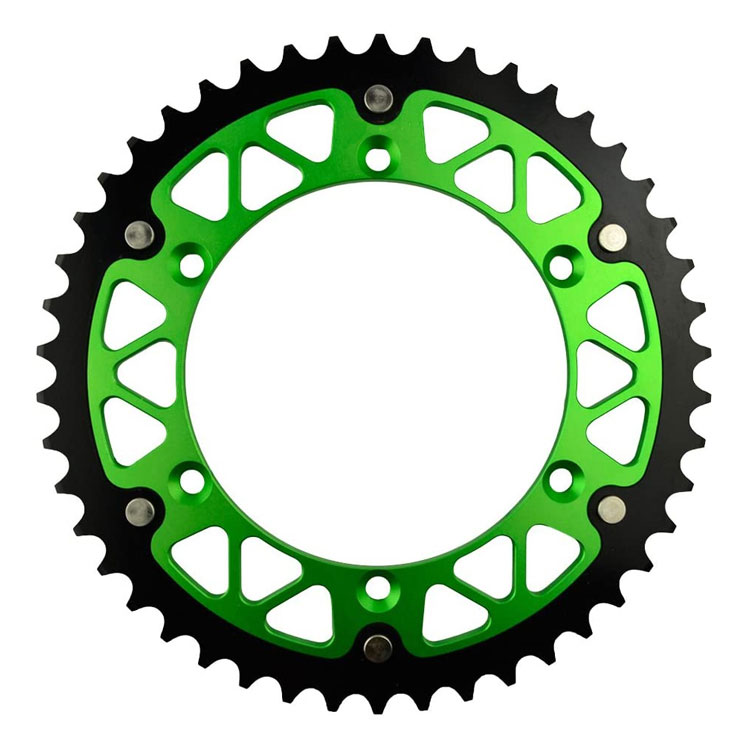

Our sprockets is the world's leading brand of sprockets for motorcycle,powersport,dirt bike,ATV and UTV.Using only the finest raw materials and using cutting edge technology in their production, our range gives you the ultimate in replacement sprockets at unbeatable value.We can customize front and rear sprockets of various models and tooth numbers according to your requirements.

We ensure that the specifications of advanced power transfer chains meet or exceed the requirements of all modern motorcycles, be it street, motocross, off-road or ATV. Available in all sizes, a full range is available for all types of motorcycle in black,nickel,golden or colored finish.Includes rivet type master link,Longer chain life and less frequent chain maintenance.

Our Sprockets and chains is the world's leading Supplier of aftermarket sprockets and chains, constantly raising the industry's standards for quality and service. We are committed to supplying the most durable, best quality sprocket and chains available in the marketplace worldwide.

Our sprockets are made using only the best available materials. Aviation-grade 7075-T6 aluminium alloy for lightweight competition sprockets, SCM420 chromoly steel alloy for front sprockets, and we are sprocket Supplier using the ultra-durable high carbon 45# steel/A3 steel for rear sprockets.

Our research and development engineers not only need to be responsible for researching, testing and developing new products, making the products more practical and higher quality, but also responsible for troubleshooting and improving production process in production, including reducing waste and improving production efficiency.

The essence of a high quality sprocket is in the high precision of manufacturing and the inherent quality of the material. Through accurate machining, Our ensures maximum durability and performance.Our Sprockets are manufactured the right way by hobbing, machining and drilling. This is the only proven way to achieve the closest of tolerances and the most accurate teeth profiles.

Heat treated and hand finished to perfection, all sprockets meet or exceed the highest possible quality standards set for the motorcycle industry.

Every sprocket goes through up to 25 production stages and 10 individual quality control checks before it is ready to leave the factory and the production facility has achieved the highest European quality standards.

Every batch of our manufactured products are subject to rigorous quality testing, including applicability testing, density testing, product strength and service life testing to ensure that every batch of products leaving our factory is perfect.