Our has a motorcycle brake disc range that offers premium quality, appealing design and increasingly wide coverage. All motorcycle brake discs are maximized for safety and performance using an extremely high-grade Stainless steel 420 (2Cr13). one of the leading brands in the independent aftermarket, your first choice when it comes to motorcycle brake discs!

Our is proud to offer a wide range of brake pads for motorcycles, ATVS and more. Our produces several different brake pads for all types of riding styles and uses. With over 13 years of friction material production and research, we have learned that one compound doesnt always do the trick across the board. If you are just looking for an OEM brake pad replacement or a high performance race brake pad, we have you covered!

Our has a motorcycle brake disc range that offers premium quality, appealing design and increasingly wide coverage. All motorcycle brake discs are maximized for safety and performance using an extremely high-grade Stainless steel 420 (2Cr13). one of the leading brands in the independent aftermarket, your first choice when it comes to motorcycle brake discs!

Our products are made using the best available materials. Aviation-grade 6061-T6/7075 aluminum alloy for lightweight competition floating brake disc, and stainless steel 420 (2Cr13) for fixed brake disc.

Our research and development engineers not only need to be responsible for researching, testing and developing new products, making the products more practical and higher quality, but also responsible for troubleshooting and improving production process in production, including reducing waste and improving production efficiency.

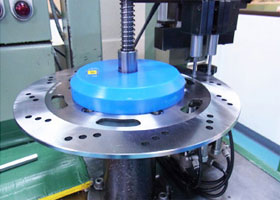

The essence of a high quality products is in the high precision of manufacturing and the inherent quality of the material. Through accurate machining, ensures products maximum durability and performance.

Heat treated and anodized finished to perfection, all products meet or exceed the highest possible quality standards set for the motorcycle industry.

Every Products goes through up to 25 production stages and 10 individual quality control checks before it is ready to leave the factory.Our quality inspection department strictly tests & monitor the entire range at every level of production.They do inspect 100% before delivery.

Every batch of our manufactured products are subject to rigorous quality testing, including applicability testing, density testing, product strength and service life testing to ensure that every batch of products leaving our factory is perfect.